Stop Cracks and Damage in Industrial Floors: Meet Smart Joint Solutions

Floors in industrial buildings and large warehouses face heavy pressure from machines and moving vehicles. Because of concrete’s natural properties and environmental conditions, cracks and joint damage can appear over time. This reduces floor performance, increases maintenance costs, and can cause safety risks.

Why is Joint and Crack Control Important?

After concrete is poured, it loses water and shrinks. If this shrinkage is not controlled, cracks and deformations happen on the floor. Heavy traffic and vibrations make these problems worse. As a result, floor durability goes down and costs go up.

How Do Smart Joint Systems Help?

Properly planned and installed joint systems control concrete shrinkage and prevent cracks. This means:

· Cracks on the floor are guided in a controlled way, keeping the floor strong.

· Safe load transfer happens between sections under heavy loads.

· Joint edges don’t break or wear out easily.

· Maintenance and repair costs go down.

· The floor looks good and stays hygienic.

Where Are These Systems Mostly Used?

1.

Industrial floors

Strong enough for heavy machines and traffic, controlling cracks and lasting

longer.

2.

Logistics warehouses and distribution centers

Protects floor joints from heavy forklift and pallet traffic, preventing damage.

3.

Airport aprons and hangars

Keeps the floor stable under dynamic loads from planes and service vehicles.

4.

Ports and container terminals

Handles heavy equipment loads and offers long-term durability.

5.

Automotive, textile, and chemical factories

Provides chemical resistance and strong mechanical performance.

6.

Food production and packaging plants

Offers safe, hygienic flooring with stainless steel options.

7.

Parking lots

Durable and reliable floors for vehicle traffic with a neat appearance.

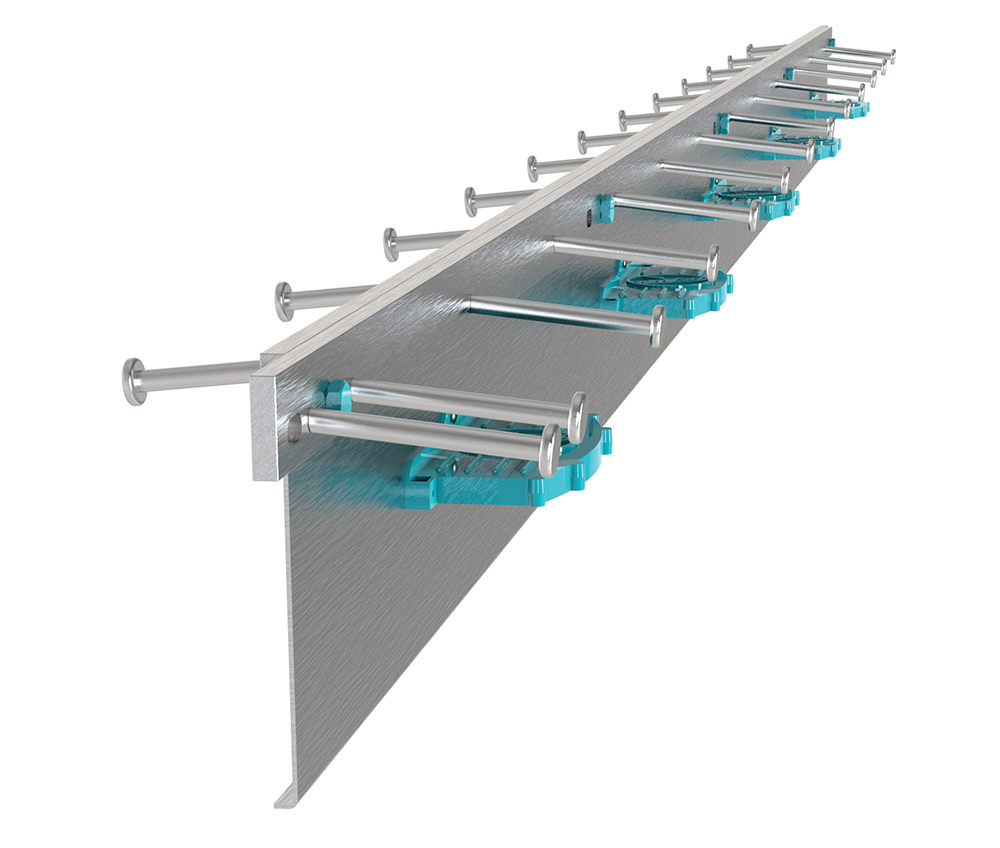

Arfen Slab Joint: Your Long-Lasting and Reliable Solution

Arfen Slab Joint systems are designed to control natural concrete movements with high-performance joint solutions. With high-quality materials and special mounting tools, they allow fast, cost-effective, and durable installation.

Increase the durability and performance of your projects with Arfen Slab Joint systems.

Türkçe

Türkçe English

English Русский

Русский