- AR 100-030 sss

- AR 101-030 sss

- AR 102-030 sss

- AR 103-030 sss

- AR 120-030 sss

- AR 300-035 sss

- AR 100-031 sss

- AR 821-030 sss

- AR 105-050 sss

- AR 106-050 sss

- AR 107-050 sss

- AR 107-051 sss

- AR 107-052 sss

- AR 107-053 sss

- AR 107-054 sss

- AR 301-050 sss

- AR 308-050 sss

- AR 703-050 sss

- AR 851-050 sss

- AR 901-050 sss

- AR 109-050 sss

- AR 500-51 sss

- AR 820-050 sss

- AR 841-050 sss

- AR 902-050 sss

- AR 902-051 sss

- AR 902-052 sss

- AR 151-050 sss

- AR 151-051 sss

- AR 153-050 sss

- AR 154-050 sss

- AR 172-050 sss

- AR 753-050 sss

- AR 883-050 sss

- AR 194-050 sss

- AR 182-050 sss

- AR 192-050 sss

- AR 193-050 sss

- AR 202-051 sss

- AR 202-050 sss

- AR 203-050 sss

- AR 212-050 sss

- AR 209-050 sss

- AR 221-050 sss

- AR 285-050 sss

- AR 287-050 sss

- AR 252-050 sss

- AR 252-051 sss

- AR 254-050 sss

- AR 255-050 sss

- AR 259-050 sss

- AR 261-050 sss

- AR 262-050 sss

- AR 262-051 sss

- AR 281-050 sss

- AR 281-050 K sss

- AR 291-050 sss

- AR 106-080 sss

- AR 109-080 sss

- AR 109-081 sss

- AR 302-080 sss

- AR 309-080 sss

- AR 713-080 sss

- AR 106-081 sss

- AR 106-100 sss

- AR 309-100 sss

- AR 303-100 sss

- AR 304-100 sss

- AR 723-100 sss

- AR 734-100 sss

- AR 823-100 sss

- AR 823-101 sss

- AR 801-100 sss

- AR 802-100 sss

- AR 813-100 sss

- AR 804-100 sss

- AR 851-100 sss

- AR 821-100 sss

- AR 901-100 sss

- AR 806-100 sss

- AR 851-125 sss

- AR 803-100 sss

- AR 841-100 sss

- AR 851-101 sss

- AR 902-100 sss

- AR 902-101 sss

- AR 902-102 sss

- AR 931-100 sss

- AR 932-100 sss

- AR 106-101 sss

- AR 202-100 sss

- AR 211-100 sss

- AR 202-102 sss

- AR 202-101 sss

- AR 221-102 sss

- AR 221-101 sss

- AR 285-100 sss

- AR 283-125 sss

- AR 203-100 sss

- AR 212-100 sss

- AR 221-100 sss

- AR 232-100 sss

- AR 233-100 sss

- AR 234-100 sss

- AR 243-100 sss

- AR 287-100 sss

- AR 236-100 sss

- AR 252-100 sss

- AR 254-100 sss

- AR 259-100 sss

- AR 261-100 sss

- AR 262-100 sss

- AR 262-101 sss

- AR 262-102 sss

- AR 281-100 sss

- AR 281-100 K sss

- AR 255-100 sss

- AR 286-100 sss

- AR 291-100 sss

- AR 293-100 sss

- AR 295-100 sss

- AR 303-150 sss

- AR 801-150 sss

- AR 802-150 sss

- AR 813-150 sss

- AR 804-150 sss

- AR 823-150 sss

- AR 823-151 sss

- AR 802-100-------------- sss

- AR 813-100------------- sss

- AR 814-100------------ sss

- AR 814-101------------ sss

- AR 821-150 sss

- AR 901-150 sss

- AR 806-150 sss

- AR 803-150 sss

- AR 309-150 sss

- AR 835-150 sss

- AR 841-150 sss

- AR 851-150 sss

- AR 902-150 sss

- AR 902-151 sss

- AR 902-152 sss

- AR 931-150 sss

- AR 932-150 sss

- AR 202-152 sss

- AR 801-150 sss

- AR 211-150 sss

- AR 212-150 sss

- AR 232-150 sss

- AR 233-150 sss

- AR 234-150 sss

- AR 236-150 sss

- AR 243-150 sss

- AR 285-150 sss

- AR 259-150 sss

- AR 295-150 sss

- AR 262-152 sss

- AR 291-150 sss

- AR 291-150 K sss

- AR 281-150 sss

- AR 286-150 sss

- AR 293-150 sss

- AR 303-200 sss

- AR 823-200 sss

- AR 823-202 sss

- AR 806-200 sss

- AR 851-200 sss

- AR 802-200 sss

- AR 803-200 sss

- AR 804-200 sss

- AR 813-200 sss

- AR 821-200 sss

- AR 835-200 sss

- AR 901-200 sss

- AR 931-200 sss

- AR 932-200 sss

- AR 232-200 sss

- AR 233-200 sss

- AR 234-200 sss

- AR 236-200 sss

- AR 243-200 sss

- AR 283-200 sss

- AR 285-200 sss

- AR 259-200 sss

- AR 295-200 sss

- AR 270DT+BTA sss

- AR 291-200 sss

- AR 281-200 sss

- AR 286-200 sss

- AR 293-200 sss

- AR 802-250 (25 cm Gap) sss

- AR 804-250 (25 cm Gap) sss

- AR 806-250 (25 cm Gap) sss

- AR 813-250 (25 cm Gap) sss

- AR 823-250 (25 cm Gap) sss

- AR 835-250 (25 cm Gap) sss

- AR 931-250 (25 cm Gap) sss

- AR 802-300 (30 cm Gap) sss

- AR 804-300 (30 cm Gap) sss

- AR 806-300 (30 cm Gap) sss

- AR 813-300 (30 cm Gap) sss

- AR 931-300 (30 cm Gap) sss

- AR 802-350 (35 cm Gap) sss

- AR 806-350 (35 cm Gap) sss

- AR 802-400 (40 cm Gap) sss

- AR 806-400 (40 cm Gap) sss

- AR 961-400 (40 cm Gap) sss

- AR 971-400 (40 cm Gap) sss

- AR 802-450 (45 cm Gap) sss

- AR 806-450 (45 cm Gap) sss

- AR 802-500 (50 cm Gap) sss

- AR 806-500 (50 cm Gap) sss

- AR 961-500 (50 cm Gap) sss

- AR 971-500 (50 cm Gap) sss

- AR 961-600 (60 cm Gap) sss

- AR 971-600 (60 cm Gap) sss

- AR 961-700 (70 cm Gap) sss

- AR 971-700 (70 cm Gap) sss

- AR 971-750 (75 cm Gap) sss

- AR 232-250 (25 cm Gap) sss

- AR 234-250 (25 cm Gap) sss

- AR 236-250 (25 cm Gap) sss

- AR 243-250 (25 cm Gap) sss

- AR 232-300 (30 cm Gap) sss

- AR 234-300 (30 cm Gap) sss

- AR 236-300 (30 cm Gap) sss

- AR 243-300 (30 cm Gap) sss

- AR 232-350 (35 cm Gap) sss

- AR 236-350 (35 cm Gap) sss

- AR 232-400 (40 cm Gap) sss

- AR 236-400 (40 cm Gap) sss

- AR 232-450 (45 cm Gap) sss

- AR 236-450 (45 cm Gap) sss

- AR 232-500 (50 cm Gap) sss

- AR 236-500 (50 cm Gap) sss

- AR 281-250 (25 cm Gap) sss

- AR 286-250 (25 cm Gap) sss

- AR 291-250 (25 cm Gap) sss

- AR 293-250 (25 cm Gap) sss

- AR 281-300 (30 cm Gap) sss

- AR 286-300 (30 cm Gap) sss

- AR 291-300 (30 cm Gap) sss

- AR 293-300 (30 cm Gap) sss

- AR 291-350 (35 cm Gap) sss

- AR 291-400 (40 cm Gap) sss

- AR 201ZD sss

- AR 100ZD sss

- AR 120ZD sss

- AR 150ZD sss

- AR 151ZD sss

- AR 200ZD sss

- AR 250ZD sss

- AR 350ZD sss

- AR 70ZD sss

- AR 100ZD1 sss

- AR 150ZD1 sss

- AR 300ZD sss

- AR 60DT sss

- AR 100DT sss

- AR 120DT sss

- AR 150DT sss

- AR 151DT sss

- AR 200DT sss

- AR 201DT sss

- AR 250DT sss

- AR 270DT sss

- AR 270DT+BTA sss

- AR 70ZD sss

- AR 100ZD1 sss

- AR 150DT1 sss

- AR 150DTR1 sss

- AR200DTR1 sss

- AR250DTR1 sss

- AR 4070K sss

- AR 5080K sss

- AR 50100K sss

- AR 50150K sss

- AR 50200K sss

- AR 50101K sss

- AR 50151K sss

- AR 50201K sss

- AR 2545K1 sss

- AR 3565K1 sss

- AR 50100K1 sss

- AR 100ZS sss

- AR 120ZS sss

- AR 150ZS sss

- AR 200ZS sss

- AR 100DS sss

- AR 120DS sss

- AR 150DS sss

- AR 200DS sss

- AR 4080ZKS sss

- AR 4080DKS sss

- AR 911-050 sss

- AR 911-051 sss

- AR 951-050 sss

- AR 921-051 sss

- AR 910-050 sss

- AR 921-050 sss

- ARBRIDGE01 sss

- ARBRIDGE02 sss

- ARBRIDGE03 sss

- ARBRIDGE04 sss

- AR 921-200 (20 cm Gap) sss

- AR 951-180 (20 cm Gap) sss

- AR 951-250 (25 cm Gap) sss

- AR 951-300 (30 cm Gap) sss

- AR 911-200 (20 cm Gap) sss

- AR 911-250 (25 cm Gap) sss

- AR 921-250 (25 cm Gap) sss

- AR 911-300 (30 cm Gap) sss

- AR 921-300 (30 cm Gap) sss

- ARBRIDGE CARPARK 01 sss

- AR 606 series Expansion joints Detail for Roof & Coping sss

- AR 606 Corner Detail for Expansion Joints on Roof sss

- AR 605 Serisi series Expansion joints Detail sss

- AR 605 Series Corner Expansion Joint Detail sss

- ARH 20 sss

- ARH 22 sss

- ARH 25 sss

- ARH 30 sss

- ARH 35 sss

- ARH 40 sss

- AR 600-050 sss

- AR 600-050SS sss

- AR 600-100 sss

- AR 600-100SS sss

- AR 600-101 sss

- AR 600-101SS sss

- AR 600-150 sss

- AR 600-150SS sss

- AR 600-200 sss

- AR 600-200SS sss

- HYDROFLEX 600 sss

- AR 500-030 - Thermoplastic Dilatation Tape sss

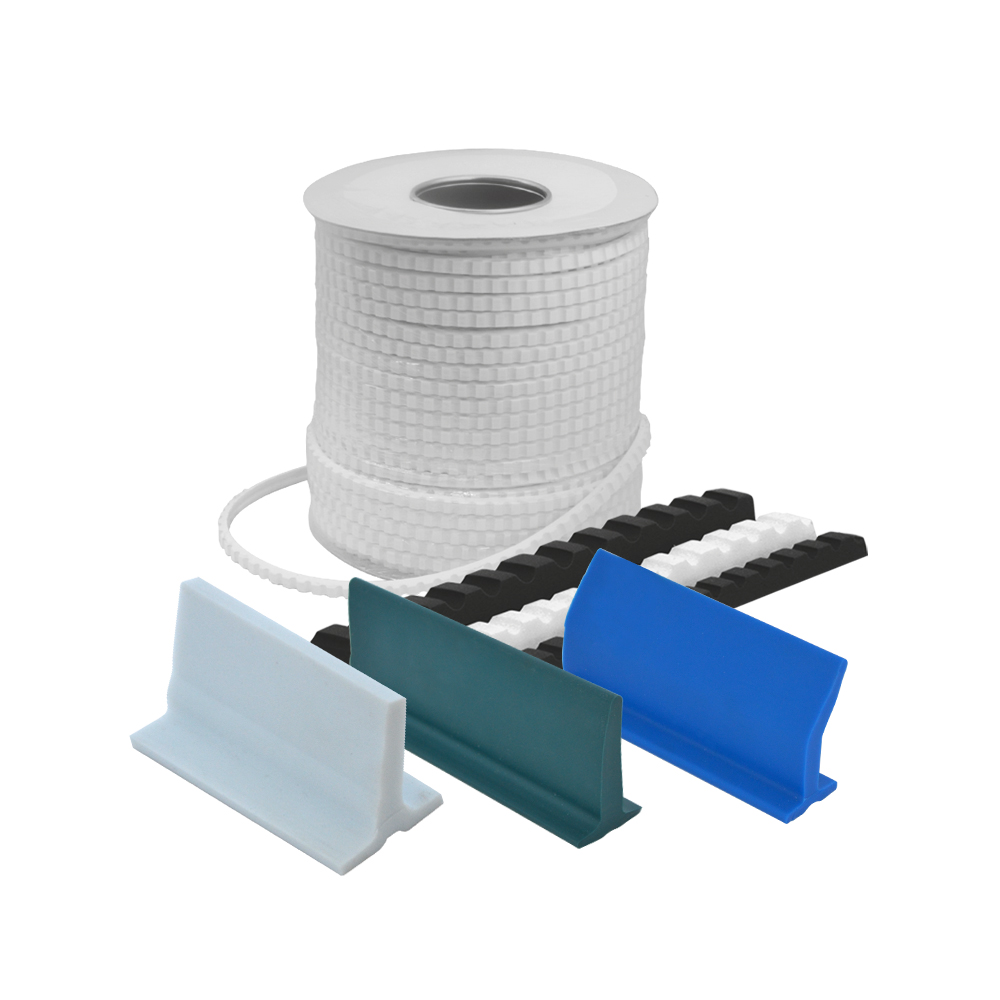

- AR 500-01 - Special Rubber Joint Profiles sss

- AR 500-02 - Special Rubber Joint Profiles sss

- AR 500-03 - Special Rubber Joint Profiles sss

- AR 500-04 - Special Rubber Joint Profiles sss

- AR 500-05 - Special Rubber Joint Profiles sss

- AR 500-06 - Special Rubber Joint Profiles sss

- HYDROFLEX EPOXY MORTAR sss

- AR 500-01A- Special Rubber Joint Profiles sss

- AR 500-01B- Special Rubber Joint Profiles sss

- AR 500-01C- Special Rubber Joint Profiles sss

- AR 500-02A - Special Rubber Joint Profiles sss

- AR 500-07 - Special Rubber Joint Profiles sss

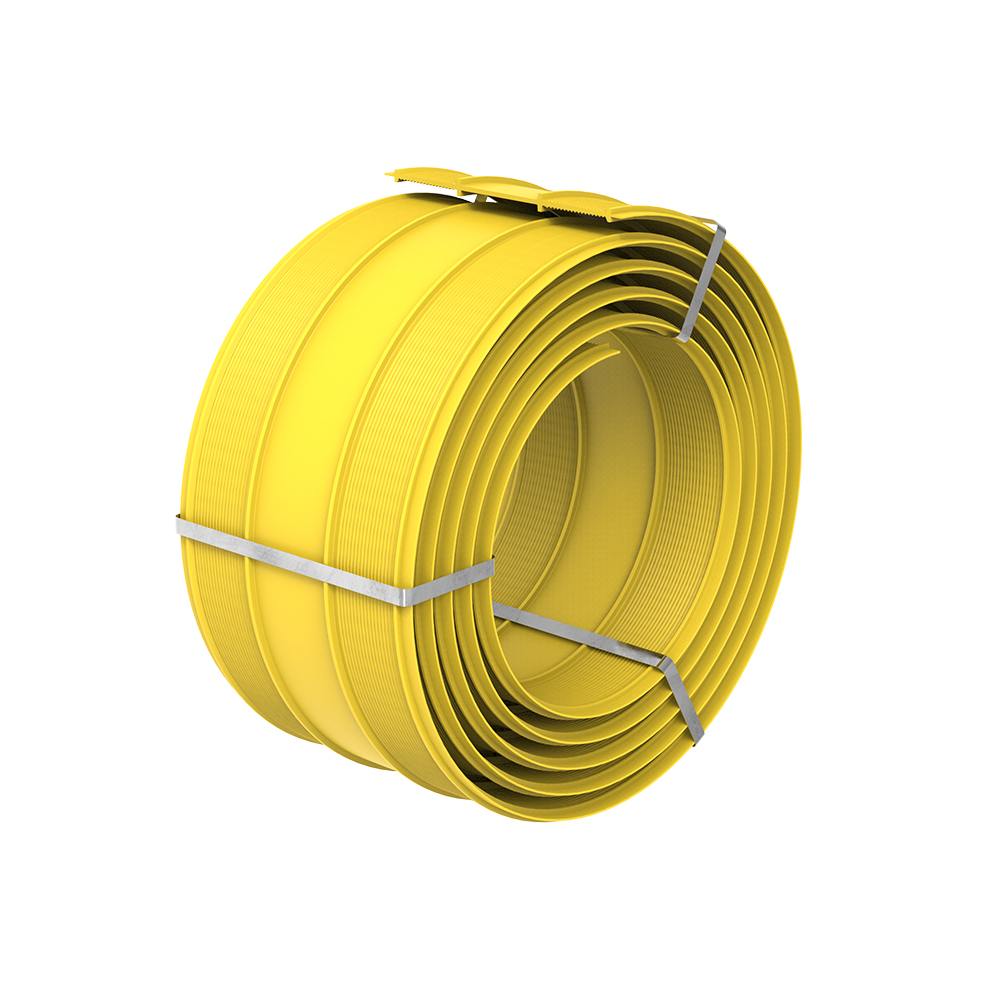

- AR 500-101 Thermoplastic Expansion Joint Bands sss

- AR 500-05A - Special Rubber Joint Profiles sss

- WG 150 sss

- WG 200 sss

- WG 201 sss

- CR 50 sss

- WG 100 sss

- DC 100 sss

- DC 150 sss

- DC 200 sss

- WG 150-2 sss

- WG 101 sss

- WG101 with Bracket sss

- WG 150-1 sss

- WG 102 sss

- WG 145 sss

- WG 152 sss

- DC 140 sss

- WG 145-1 LED Lighting Handrail sss

- WG 153 sss

- WG 146 sss

- WG 152-1 COMBO RAIL sss

- WG 100SS sss

- WG 170SS sss

- CG 50 sss

- CG 50B sss

- CG 76 sss

- CG 76A sss

- DK 20 sss

- DK 30 sss

- DK 40 sss

- CG 25B sss

- CG 51 sss

- CG 76B sss

- IK08 sss

- IK10 sss

- IK12 sss

- IK10P sss

- SB0106 sss

- SB0108 sss

- SB0110 sss

- SB0112 sss

- SB0206 sss

- SB02 sss

- SB0201 sss

- SB03 sss

- SB12 sss

- SB04 sss

- SB05 sss

- SB06 sss

- SB07 sss

- SB08 sss

- SB09 sss

- SB15 sss

- SB07-25 sss

- MB 25 sss

- MB35 sss

- MB40 sss

- MB45 sss

- MB 75-2 sss

- MB55 sss

- MB55P sss

- MB36 sss

- MB41 sss

- MB50 sss

- SB10 sss

- SB1012 sss

- SB11 sss

- SB1112 sss

- MB40-25 sss

- MB55-1 sss

- MB76 sss

- HB18 sss

- HB25 sss

- KB19 sss

- KB25 sss

- GP25 sss

- GP01 sss

- GP30 sss

- GP30-2 sss

- GP32 sss

- GP35 sss

- GP37 sss

- GP38 sss

- GP39 sss

- GP41 sss

- GP50 sss

- GP40 sss

- PS85- Economic Elastic PVC Skirting with Cap sss

- PS86-Elastic PVC Skirting with Cap sss

- PS5510-Elastic PVC Skirting with Cap sss

- PS7510-Elastic PVC Skirting with Cap sss

- PS9010-Elastic PVC Skirting with Cap sss

- PS10010-Sit-on PVC Skirting sss

- MB55P-Stair Nosing Profile sss

- PS3030-Plaster Bottom Cushion sss

- PS28-Cap Profile sss

- PS0004-4 mm Welding Rod sss

- PS2020-Plaster Bottom Cushion sss

- PS100-Elastic PVC Skirting sss

- SB03-01 sss

- SB12-01 sss

- SB05-01 sss

- SB07-01 sss

- SB08-01 sss

- SB08-20 sss

- DP05-01 sss

- ASP60-01 sss

- İK10-02 sss

- CG30S sss

- CG50S sss

- CG75S sss

- CG100S sss

- SB 51 sss

- SB 52 sss

- SB 53 sss

- SB 54 sss

- SB 55 sss

- SB 56 sss

- SB 57 sss

- SB 58 sss

- SB 59 sss

- SB 60 sss

- SB 61 sss

- ARF 10 sss

- ARF 10-1 sss

- ARF 10-2 sss

- ARF 15 sss

- ARF 30 sss

- ARF 30-1 sss

- ARF 40x15 sss

- ARF 40x23x15 sss

- ARF 50 sss

- DP01-08 sss

- DP01-06 sss

- DP01-23 sss

- DP01-16 sss

- DP01-14 sss

- DP01-12 sss

- DP01-10 sss

- DP01-25 sss

- DP07-14 sss

- DP01-60 sss

- HYDROFLEX 150 sss

- HYDROFLEX 200 sss

- HYDROFLEX 250 sss

- HYDROFLEX 300 sss

- HYDROFLEX 400 sss

- HYDROFLEX 21 Dilatation Band Adhesive sss

- HYDROFLEX 500 sss

- HYDROFLEX 550 sss

- HYDROFLEX 120 (Mesh Reinforced) sss

- HYDROFLEX 120 IK sss

- HYDROFLEX 120 DK sss

- HYDROFLEX 121 ( Felt Reinforced) sss

- HYDROFLEX 121 İK sss

- HYDROFLEX 121 DK sss

- Hydroflex 5/20 sss

- Hydroflex 10/20 sss

- Hydroflex 5/20 B sss

- Hydroflex 10/20 B sss

- Hydroflex 5/20T sss

- Hydroflex 10/20T sss

- AR 2002 sss

- AR 2001 sss

- AR 2003 sss

- AR 2004 sss

- AR 2005 sss

- AR 2006 sss

- AR 2007 sss

- AR 2008 sss

- AR 2009 sss

- HYDROFLEX WATERTEX 01 sss

- HYDROFLEX WATERTEX 02 sss

- HYDROFLEX WATERTEX 03 sss

- HYDROFLEX WATERTEX 04 sss

- HYDROFLEX WATERTEX 100 sss

- HYDROFLEX WATERTEX 100/PRO sss

- HYDROFLEX WATERTEX 120 sss

- HYDROFLEX WATERTEX 120/PRO sss

- HYDROFLEX WATERTEX 1000 sss

- EBOND-01 sss

- EBOND-04 sss

- EBOND-06 sss

- AR-CHEM GROUT sss

- AR-CHEM GROUT / PRO sss

- HYDROFLEX 21 sss

- HYDROFLEX EPOXY MORTAR sss

- HYDROFLEX PU PRIMER 1K sss

- HYDROFLEX PU PRIMER 2K sss

- HYDROFLEX EPO PRIMER 2K sss

- HYDROFLEX EPO PRIMER 2K / PRO sss

- AR-CHEM REPAIR 01 sss

- AR-CHEM REPAIR 02 sss

- AR-CHEM REPAIR 03 sss

- AR-CHEM REPAIR 05 sss

- AR-CHEM LATEX sss

- BB-020/1 sss

- BB-030/1 sss

- BB-050/1 sss

- BB-100/1 sss

- BB-200/1 sss

- BBA01-050/1 sss

- BBA01-100/1 sss

- BBA01-150/1 sss

- BBA01-200/1 sss

- BBA01-250/1 sss

- BBA01-300/1 sss

- BBP01-100/1 sss

- BBP01-150/1 sss

- BBP01-200/1 sss

- BBP01-250/1 sss

- BBP01-300/1 sss

- BBP02-100/1 sss

- BBP02-150/1 sss

- HYDROFLEX 25 SL sss

- HYDROFLEX 35 PU sss

- HYDROFLEX 40 FC sss

- HYDROFLEX 40 MS sss

- PS JOINT 01 sss

- PS JOINT 02 sss

- PS PRIMER sss

- HYDROFLEX PU 1K sss

- HYDROFLEX PU 1K / UV sss

- HYDROFLEX MS 1K sss

- HYDROFLEX AC 1K sss

- HYDROFLEX PU PAINT sss

- HYDROFLEX POLY 101 sss

- HYDROFLEX POLY 102 sss

- HYDROFLEX POLY 103 sss

- HYDROFLEX POLY 104 sss

- HYDROFLEX POLY 105 sss

- HYDROFLEX POLY REPAIR sss

- HYDROFLEX BITUMEN 1K sss

- HYDROFLEX BITUMEN 2K sss

- HYDROFLEX BITUMEN PRIMER 01 sss

- HYDROFLEX BITUMEN PRIMER 02 sss

- HYDROFLEX BITUMEN J01 sss

- HYDROFLEX BITUMEN J02 sss

- HYDROFLEX BITUMEN PU 1K sss

- HYDROFLEX BITUMEN PU 2K sss

- AR-CHEM 1K CAPILLAR sss

- AR-CHEM 2K sss

- AR-CHEM 2K FLEX sss

- AR-CHEM 2K UV sss

- AR-CHEM 2K CAPILLAR sss

- AR-CHEM WATERSTOP sss

- AR-CHEM TURBO WATERSTOP sss

- PS53-Carpet Type Skirting sss

- PS45-Top Plaster Skirting sss

- ASP80P-PVC Skirting sss

- DC101-Decorative PVC Skirting with Cable Channel sss

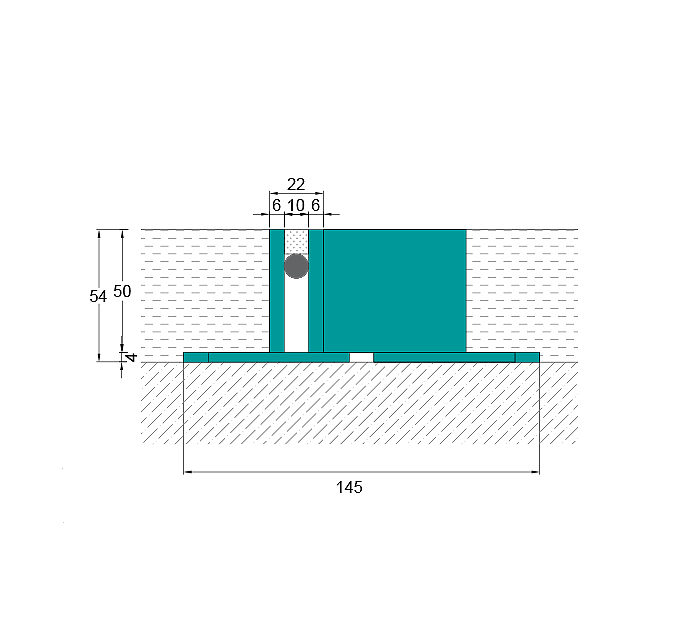

RP 01 - REPAIR JOINT

Damaged joints pose a significant problem for all factories and warehouses. These types of joints, which have been opened using traditional methods, begin to deteriorate over time due to the impact of passing wheel loads, material drops, and similar situations. What starts as a small crack can escalate into serious issues over time.

However, advancing technology is leading to the replacement of the carrier vehicles used in factories and/or warehouses with more modern ones. Tire-wheel and gasoline-powered forklifts are being replaced by electric, small, solid-wheel ones. These types of carriers subject joints to more impact compared to tire-wheel ones, further accelerating damage. When damage begins to occur in these joints, quick repairs are necessary. However, to ensure sustainability, a more accurate and long-lasting system should be chosen instead of mortar for repairs. Repaired joints using only mortar will eventually experience this type of damage again under repeated loads. This is where the Arfen Repair Joint system comes into play. It provides a permanent solution against the damage caused by repetitive wheel loads and impact effects on industrial floors and joints, while also reducing sound and vibration thanks to its trapezoidal shape.

Benefits

• Provides a permanent solution for joint repairs.

• Protects joints against impact thanks to its trapezoidal shape.

• Reduces noise and vibration.

• Does not require maintenance after installation