HYDROFLEX EPOXY MORTAR

Product description:

Solvent-free, 3 components , repair mortar is a combination of specially graded aggregates and high strength epoxy resin. After mixing, the consistency is applied with a trowel can offer very good adhesion to cement surfaces

Usage areas:

To Bring the expansion joint profiles to the ground level,

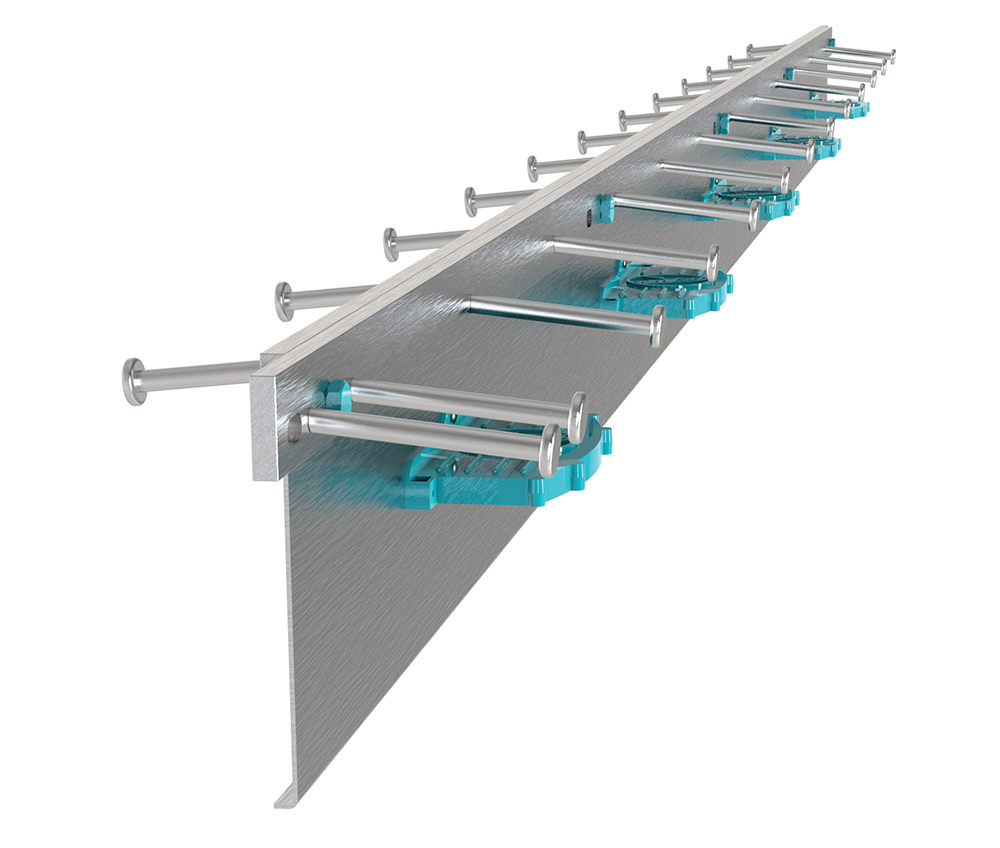

The Anchor works,

Bearing in concrete

Fill mortar or as a high-strength material for the repair of horizontal concrete surfaces

Crane Rails Applications

For Bridge Bearings support,

In the repair of aircraft and helicopter runway

Fixing of steel columns and pillars,

On the basis of all kinds of industrial machinery space

Subway, highway and engineering structures such as dams,

Repairs, maintenance and enhancement projects for the place where the beams of the reinforced concrete wall,

The installation of prefabricated elements.

Technical Information:

|

Packing:

20 Kg. Pack.. The composition of : Component A ; 1.67 Kg Component B; 0,83 Kg Component C: 17,50 Kg

Türkçe

Türkçe English

English Русский

Русский